选型指南:

型号 Mode | 两相步进驱动器SA-872E |

输入电压 Power Supply | 20~80VAC/24-110VDC |

输出电流 Output current | 2.2~8.2A |

控制功能 Control Modes | 脉冲+方向 |

细分 Subdivisions | 400~51200 |

控制信号接口电平 Control Signal Voltage | 5-24VDC |

机械尺寸 Domensions | 97.5*1500*52.6 |

可定制型号:

型号Model | 功能说明 Function description |

SA-872E | 脉冲+方向(SW9状态ON为双脉冲) |

SA-872EC | IO控制(SW9状态ON为双脉冲) |

SA-865EV | 脉冲+方向(SW9状态ON为双脉冲) 电位器调速 |

SA-872EA | 脉冲+方向(SW9状态ON为双脉冲) 报警输出 |

★C:IO控制;★V:电位器调速;★A:报警输出

运行模式设定:

不含IO控制功能的型号 | |||

功能 | 开关 | 状态 | 结果 |

单双脉冲设置 | SW9 | OFF | 单脉冲 |

ON | 双脉冲 | ||

空闲电流设置 | SW10 | OFF | 半流 |

ON | 全流 | ||

★驱动器运行电流,在马达停转时刻自动减少,SW10设定空闲电流为运行电流的50%或100%,

当需要一个高力矩时,设为全流。为减少电机和驱动器的热量,推荐将空闲电流在允许的情况下尽可能降低。

含IO控制功能的型号 | ||

运行模式 | SW9 | SW10 |

单脉冲(默认) | OFF | OFF |

双脉冲 | ON | OFF |

受控运行 | OFF | ON |

持续运行 | ON | ON |

★IO控制模式时内置振荡器,拨码或开关量信号控制电机启停,可外接电位器或电压调速。电机默认自动半流。

报警代码:

绿色LED为电源指示灯,驱动器接通电源时,绿灯闪烁;切断驱动器电源时,绿灯熄灭。

红色LED为故障指示灯,出现故障时,红灯周期性循环闪烁;故障清除后,红灯熄灭。驱动器正常工作。

红灯闪烁次数代表不同的故障,具体关系如下:

LED灯状态 | 驱动器状态 |

绿灯常亮 | 电机运行中 |

绿灯闪烁 | 电机空闲 |

1红+1绿 | 相位过流 |

2红+1绿 | 电机绕组开路 |

3红+1绿 | 驱动器过压 |

4红+1绿 | 驱动器欠压 |

5红+1绿 | 其他 |

工作电流设定(SW1~SW3)

峰值 | SW1 | SW2 | SW3 | SW4 |

2.2A | OFF | OFF | OFF | OFF |

2.6A | ON | OFF | OFF | OFF |

3.0A | OFF | ON | OFF | OFF |

3.4A | ON | ON | OFF | OFF |

3.8A | OFF | OFF | ON | OFF |

4.2A | ON | OFF | ON | OFF |

4.6A | OFF | ON | ON | OFF |

5.0A | ON | ON | ON | OFF |

5.4A | OFF | OFF | OFF | ON |

5.8A | ON | OFF | OFF | ON |

6.2A | OFF | ON | OFF | ON |

6.6A | ON | ON | OFF | ON |

7.0A | OFF | OFF | ON | ON |

7.4A | ON | OFF | ON | ON |

7.8A | OFF | ON | ON | ON |

8.2A | ON | ON | ON | ON |

驱动器的峰值电流设置必须小于匹配电机的额定电流,否则可能会导致电机温升过高,影响电机使用寿命。

细分设定(SW5~SW8)

细分 | SW5 | SW6 | SW7 | SW8 |

400 | ON | ON | ON | ON |

800 | OFF | ON | ON | ON |

1600 | ON | OFF | ON | ON |

3200 | OFF | OFF | ON | ON |

6400 | ON | ON | OFF | ON |

12800 | OFF | ON | OFF | ON |

25600 | ON | OFF | OFF | ON |

51200 | OFF | OFF | OFF | ON |

1000 | ON | ON | ON | OFF |

2000 | OFF | ON | ON | OFF |

4000 | ON | OFF | ON | OFF |

5000 | OFF | OFF | ON | OFF |

8000 | ON | ON | OFF | OFF |

10000 | OFF | ON | OFF | OFF |

20000 | ON | OFF | OFF | OFF |

40000 | OFF | OFF | OFF | OFF |

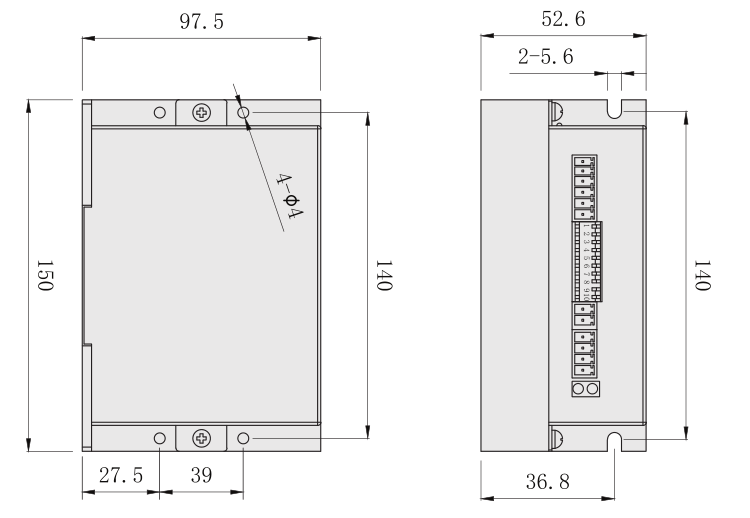

外形尺寸图(单位:mm)

IO控制模式时速度设定表

速度 | SW5 | SW6 | SW7 | SW8 |

5 | ON | ON | ON | ON |

10 | OFF | ON | ON | ON |

15 | ON | OFF | ON | ON |

30 | OFF | OFF | ON | ON |

60 | ON | ON | OFF | ON |

90 | OFF | ON | OFF | ON |

120 | ON | OFF | OFF | ON |

150 | OFF | OFF | OFF | ON |

180 | ON | ON | ON | OFF |

210 | OFF | ON | ON | OFF |

240 | ON | OFF | ON | OFF |

300 | OFF | OFF | ON | OFF |

400 | ON | ON | OFF | OFF |

500 | OFF | ON | OFF | OFF |

650 | ON | OFF | OFF | OFF |

800 | OFF | OFF | OFF | OFF |

选型指南:

型号 Mode | 两相步进驱动器SA-872E |

输入电压 Power Supply | 20~80VAC/24-110VDC |

输出电流 Output current | 2.2~8.2A |

控制功能 Control Modes | 脉冲+方向 |

细分 Subdivisions | 400~51200 |

控制信号接口电平 Control Signal Voltage | 5-24VDC |

机械尺寸 Domensions | 97.5*1500*52.6 |

可定制型号:

型号Model | 功能说明 Function description |

SA-872E | 脉冲+方向(SW9状态ON为双脉冲) |

SA-872EC | IO控制(SW9状态ON为双脉冲) |

SA-865EV | 脉冲+方向(SW9状态ON为双脉冲) 电位器调速 |

SA-872EA | 脉冲+方向(SW9状态ON为双脉冲) 报警输出 |

★C:IO控制;★V:电位器调速;★A:报警输出

运行模式设定:

不含IO控制功能的型号 | |||

功能 | 开关 | 状态 | 结果 |

单双脉冲设置 | SW9 | OFF | 单脉冲 |

ON | 双脉冲 | ||

空闲电流设置 | SW10 | OFF | 半流 |

ON | 全流 | ||

★驱动器运行电流,在马达停转时刻自动减少,SW10设定空闲电流为运行电流的50%或100%,

当需要一个高力矩时,设为全流。为减少电机和驱动器的热量,推荐将空闲电流在允许的情况下尽可能降低。

含IO控制功能的型号 | ||

运行模式 | SW9 | SW10 |

单脉冲(默认) | OFF | OFF |

双脉冲 | ON | OFF |

受控运行 | OFF | ON |

持续运行 | ON | ON |

★IO控制模式时内置振荡器,拨码或开关量信号控制电机启停,可外接电位器或电压调速。电机默认自动半流。

报警代码:

绿色LED为电源指示灯,驱动器接通电源时,绿灯闪烁;切断驱动器电源时,绿灯熄灭。

红色LED为故障指示灯,出现故障时,红灯周期性循环闪烁;故障清除后,红灯熄灭。驱动器正常工作。

红灯闪烁次数代表不同的故障,具体关系如下:

LED灯状态 | 驱动器状态 |

绿灯常亮 | 电机运行中 |

绿灯闪烁 | 电机空闲 |

1红+1绿 | 相位过流 |

2红+1绿 | 电机绕组开路 |

3红+1绿 | 驱动器过压 |

4红+1绿 | 驱动器欠压 |

5红+1绿 | 其他 |

工作电流设定(SW1~SW3)

峰值 | SW1 | SW2 | SW3 | SW4 |

2.2A | OFF | OFF | OFF | OFF |

2.6A | ON | OFF | OFF | OFF |

3.0A | OFF | ON | OFF | OFF |

3.4A | ON | ON | OFF | OFF |

3.8A | OFF | OFF | ON | OFF |

4.2A | ON | OFF | ON | OFF |

4.6A | OFF | ON | ON | OFF |

5.0A | ON | ON | ON | OFF |

5.4A | OFF | OFF | OFF | ON |

5.8A | ON | OFF | OFF | ON |

6.2A | OFF | ON | OFF | ON |

6.6A | ON | ON | OFF | ON |

7.0A | OFF | OFF | ON | ON |

7.4A | ON | OFF | ON | ON |

7.8A | OFF | ON | ON | ON |

8.2A | ON | ON | ON | ON |

驱动器的峰值电流设置必须小于匹配电机的额定电流,否则可能会导致电机温升过高,影响电机使用寿命。

细分设定(SW5~SW8)

细分 | SW5 | SW6 | SW7 | SW8 |

400 | ON | ON | ON | ON |

800 | OFF | ON | ON | ON |

1600 | ON | OFF | ON | ON |

3200 | OFF | OFF | ON | ON |

6400 | ON | ON | OFF | ON |

12800 | OFF | ON | OFF | ON |

25600 | ON | OFF | OFF | ON |

51200 | OFF | OFF | OFF | ON |

1000 | ON | ON | ON | OFF |

2000 | OFF | ON | ON | OFF |

4000 | ON | OFF | ON | OFF |

5000 | OFF | OFF | ON | OFF |

8000 | ON | ON | OFF | OFF |

10000 | OFF | ON | OFF | OFF |

20000 | ON | OFF | OFF | OFF |

40000 | OFF | OFF | OFF | OFF |

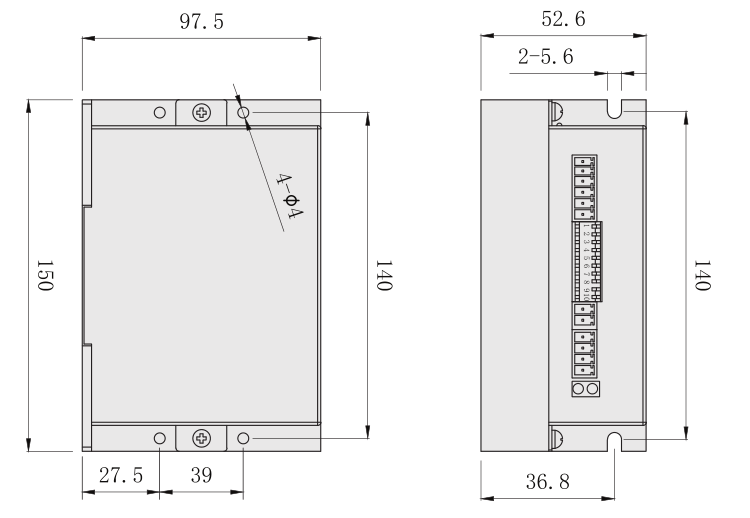

外形尺寸图(单位:mm)

IO控制模式时速度设定表

速度 | SW5 | SW6 | SW7 | SW8 |

5 | ON | ON | ON | ON |

10 | OFF | ON | ON | ON |

15 | ON | OFF | ON | ON |

30 | OFF | OFF | ON | ON |

60 | ON | ON | OFF | ON |

90 | OFF | ON | OFF | ON |

120 | ON | OFF | OFF | ON |

150 | OFF | OFF | OFF | ON |

180 | ON | ON | ON | OFF |

210 | OFF | ON | ON | OFF |

240 | ON | OFF | ON | OFF |

300 | OFF | OFF | ON | OFF |

400 | ON | ON | OFF | OFF |

500 | OFF | ON | OFF | OFF |

650 | ON | OFF | OFF | OFF |

800 | OFF | OFF | OFF | OFF |

18825289603